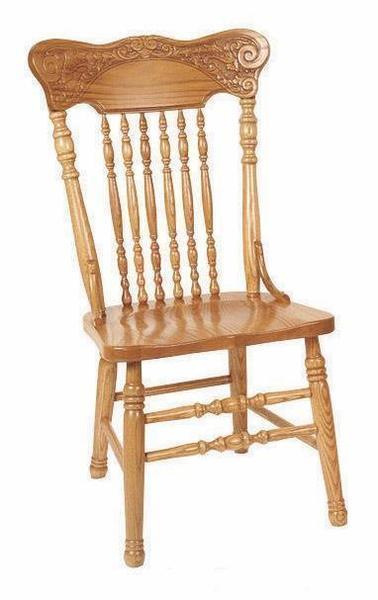

The Pressback Dining Chair

A pressback dining chair brings home the look and feel of hand carved wood. Pressback chairs feature intricate designs in the chair crest rail. The designs are often leaves or acorns or a combination of the two. These designs are no longer carved by hand, and craftsmen have found ways to produce pressbacks more quickly and efficiently. How are they made in Amish country? Let’s take a look at the pressback chair, a popular choice for country style kitchens and dining rooms.

What is a pressback chair?

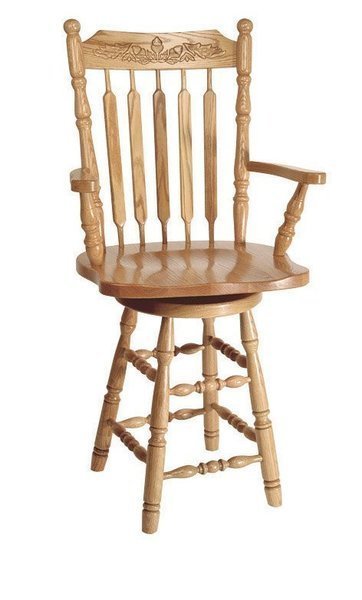

Pressback chairs bring a little of the past to the present, bringing the look of hand carving to the kitchen table. Timeless and warm, pressback chairs feature curves, turned legs, and the main event of a pressback, the chair crest or back displaying a pressed pattern.

How are pressback chairs made?

Speaking with Harvey from Hillside Chair, one of our Amish woodshops located in Ohio that creates chairs for the Hillview Chair Collection, we learned just what goes into making a pressback chair in Amish country. The process involves steam bending the back of the chair first. Then, a steel die is used. The steel die is a mold with a pattern in it. The die is then heated to a temperature that’s just hot enough that it will not burn the wood. Then, the die is pressed into the wood back, applying several pounds of pressure per square inch. There are different steel dies for different patterns, like flowers, acorns, etc. Once pressed into the back, the steel die creates the look of a three dimensional carving.

History of the Pressback Chair

During the Golden Age or Golden Oak Period of the 1870s, elaborate hand carving was popular. Craftsmen began using oak wood more, and a standout for hand carving fine oak furniture was a man named Robert J. Horner. Coats of orange shellac with a yellow tint were applied to oak wood to produce a golden glow, contributing to the “Golden Oak Period.”

As technology advanced, it brought hand carving practices to an end by the close of the 19th century. While the wealthy could afford hand carving, they didn’t like having to wait so long for the work to be completed. Tools developed to replace hand carving included the spindle carver, router and die press.

For the steel die, crucial for pressback chairs and benches, designs were added to steel plates that were mounted on rollers. Pressure was applied to the steel die as it rolled over the wood canvas of the chair back, achieving a hand carved look in less time. The design was transferred to the wood, literally pressing it in, hence the name “pressback chair” came to be.

Pressback dining chairs were popular during the 1800s and 1900s. Many were sold through catalogs. Consumers wanted the look of a hand carved back without the wait time. In addition, the pressed design was more affordable than hand carving. Oak double pressback chairs became stars of mail order catalogs since they looked stunning and were made fast. (A double pressback features a pressback on both sides of the chair crest, not just one side.)

Amish Made Pressback Chairs

DutchCrafters Amish pressback chairs continue to bring home a hand carved look and feel. The Hillview Chair Collection crafted in Ohio produces fine wood dining chairs in mission, shaker, French country, Queen Anne and country styles. Spindles, legs, dowels and chair backs are sculpted with precision and thoroughly inspected. Time is made for all the details that make these chairs stand out from others, things like hand sanding and a thorough stain that even includes the bottom side of the seat. Legs are glued and screwed to the seat, and chair backs protrude through the seat and are glued and screwed for maximum strength and stability.

For Hillview’s popular pressback design, you’ll find the acorns in the chair crest turned up and not down, because that’s how acorns grow on trees. That is just one of the little details Amish craftsmen keep in mind when crafting pressbacks!

If you love the look of hand carving, you’ve found it in the fine pressback dining chairs made in Amish country.

How do I get prices and place order?

Hello Tom,

You can select the category of furniture that interests you in the drop-down options in the header at the top of the page. You can then click on any product to go to that product page. A price will be listed there for the product.

You can click the “Select Options” button in the blue bar to the right of the page to add any upgrades, and you will see each upgrade’s additional cost there.

You can select the options you want online, or for personal assistance, feel free to contact a furniture specialist via email at questions@dutchcrafters.com or call us at (941)-867-2233.

Thank you for visiting us on Timber to Table.

What is the bent piece of wood called that connects the seat to the back of the press back chair?

Hi Sandra,

That piece has been referred to as a “hip brace,” adding some structural support to the chair.

Thank you for your question and for visiting us on Timber to Table.

Hi Beth,

We have a set of chairs in our familly but I never saw our model. Instead of having what you call the ‘’hip brace’’ the main two posts are curved. Do you know any thing about this model?

Thank you.

Hello Daniel,

When you say that the main two posts are curved, do you mean one continuous curved piece? Like a Windsor chair design? Here’s a link to a Windsor for you to compare. Thank you for your question and for visiting us on Timber to Table.

https://www.dutchcrafters.com/Amish-Colonial-9-Spindle-Windsor-Dining-Chair/p/4568