Quarter-Sawn White Oak Wood Q & A

Quarter-sawn white oak wood is known among solid wood furniture makers for its durability, strength, and firm texture. We receive a lot of questions about it. Why is it called quarter-sawn? What type of furniture is it best for? What’s with the quarter-sawn grain pattern?

Here are the answers to popular quarter-sawn white oak wood questions in our QSWO Q&A.

Why is it called quarter-sawn white oak?

Because of how it’s cut. “Quarter sawing” means the oak log is cut lengthwise then the halves are turned and cut into quarters. Then each of those pieces continues to be cut in this manner until the desired board size is achieved. The growth rings of the tree create a straight, linear grain pattern from the cuts.

Photo Credit: www.wwgoa.com

Photo Credit: www.wwgoa.com

How does quarter-sawn oak compare to plain-sawn oak?

Plain sawn, or flat sawn, involves each log being cut parallel through the log, creating an attractive swirly grain pattern. More lumber can be used from the log with this method of cutting. Plain-sawn lumber costs less and is easier to find, but there’s a risk of it cupping or bowing as it ages. Quarter-sawn wood is stronger, more stable, and more resistant to cupping, warping, and moisture.

Photo Credit: www.wwgoa.com

How does the look of quarter-sawn white oak differ from regular oak?

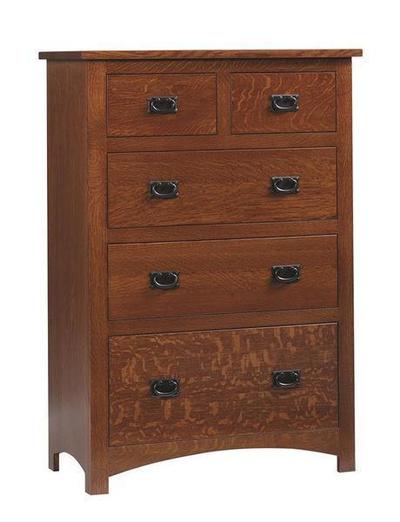

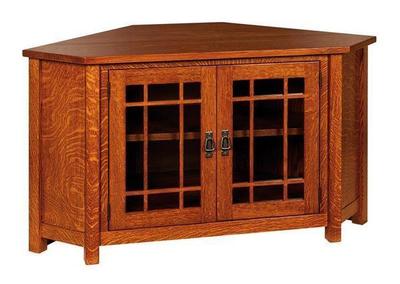

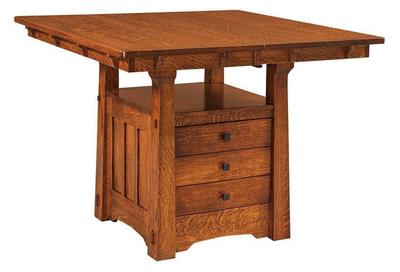

The unique way quarter-sawn white oak is cut results in a different grain pattern that’s not as thick as the regular cut pattern of oak. Quarter-sawn wood is cut across the growth rings, creating a straighter grain and adding to the stability of the wood. Along with the wood grain, what you see creating a unique pattern on quarter-sawn oak wood are medullary rays and flecks.

Medullary rays (also known as tiger marks or pith rays) are caused by plant cells that allow movement of sap throughout the trunk of the tree, perpendicular to its growth rings and contributing to the growth process. When the cuts are made, the cells create markings that stand out, often in wavy patterns, adding to a decorative nature. The markings are a sign that you’ve received a product made from a high-end wood and a lot of labor went into making it.

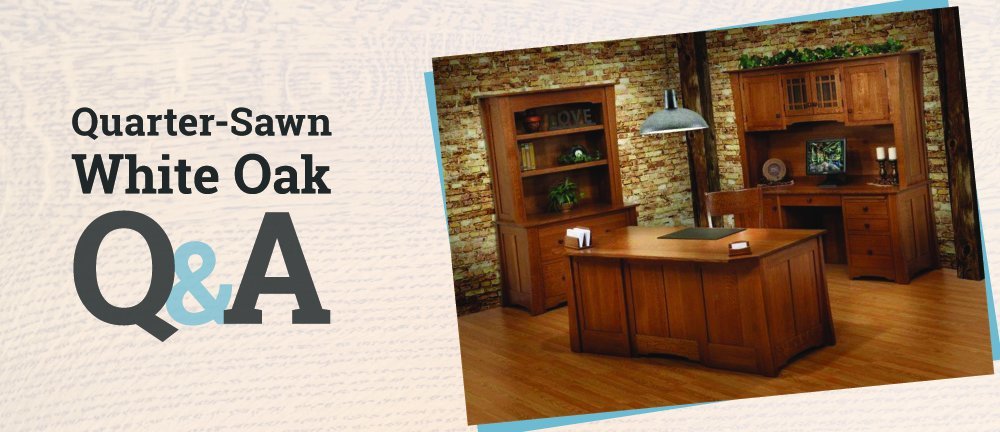

You can pick out the attractive yet unpredictable rays and flecks of the Amish Santa Rosa Work Desk.

Is quarter-sawn white oak wood stronger than regular oak?

Both are strong, reliable, and highly durable. Quarter-sawn white oak is even more stable, wears evenly and offers added resistance to twisting, cupping, and warping because of the way it’s cut. This is a desirable feature, especially for wood that is used to craft furniture.

What type of furniture is quarter-sawn white oak a good candidate for?

Due to its strength, quarter-sawn white oak is a popular pick for furniture that sees daily use. It’s a popular choice for flooring, cabinetry, and furniture. We see it used a lot for living rooms and dining furniture.

Which furniture style is quarter-sawn white oak best suited for?

Quarter-sawn white oak wood is often chosen for shaker and mission-style furniture that highlights flat panels so the grain pattern can really shine.

How can I tell it’s quarter-sawn white oak?

Quarter-sawn oak showcases varying shades of white to medium brown in its heartwood and sapwood. Because of the way the oak log is cut across the growth rings, the grain is straighter, adding to the stability of the wood. You can always look for the lovely flecks, waves, and flakes in the wood. The medullary rays create a wavy grain pattern with a decorative effect that gives the furniture a unique character.

What other questions do you have about quarter sawn white oak? What do you like or dislike about it?